● Adsorption type:

This method uses the suction force generated by the vacuum suction head of the electric screwdriver head, and the reverse suction force formed by compressed air to extract a single screw from the screw arrangement machine. The efficiency of this method is related to the walking distance and speed. It is generally suitable for screws with relatively small length and light weight, and the upper surface of the screw head can form a certain air tightness with the vacuum suction head cavity of the electric screwdriver. The suction type screw feeding can customize the vacuum suction cup according to the specifications and models of the screws, so the requirements for screws are not high and it is more universal.

● Air blowing type:

The screw is blown to the bottom of the screwdriver mouth by compressed air, and the electric screwdriver goes down to automatically lock it into the product. This method is generally suitable for screws below M5 and screws with a length of less than 25mm. At the same time, the total length L of the screw must be greater than 1.3 times the diameter D of the screw head, otherwise it will roll over in the feeding tube and cannot be sent out normally. The air-blowing material separation efficiency can reach 1S/Pcs.

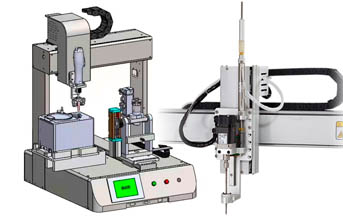

The automatic screw locking machine consists of four parts: feeding system, locking system, control system and intelligent electric screwdriver equipment. The feeding system is responsible for sending the screws to the locking system. The suction force generated by the intelligent electric screwdriver equipment adsorbs the screws on the screwdriver head, and then the locking system completes the tightening of the screws. During the whole process, the control system plays a coordinating role, allowing the various components to work together, thereby greatly improving the production efficiency of the automatic screw locking machine operation and reducing labor costs.