● The working principle of automatic screw locking machine

The automatic screw locking machine usually consists of a feeding system, a locking system, and a control system. The feeding system arranges and transports the screws to the locking position in an orderly manner, the locking system screws into the workpiece by means of electric or pneumatic tools, and the control system coordinates the movements of the various parts to ensure that the entire locking process is carried out accurately and efficiently.

● The type of automatic screw fastening robot

Handheld automatic locking screw machine

Compact and lightweight, flexible operation, suitable for small batches, multi-variety screw locking operations.

The operator usually holds the device in his hand, aligns the screws at the holes in the workpiece, and presses the start button to complete the locking.

Multi-axis automatic screw locking machine

With multiple locking shafts, multiple screws can be locked at the same time, which greatly improves production efficiency.

It is suitable for large-volume, single-variety screw locking operations, such as electronic product assembly, auto parts manufacturing, etc.

Coordinate type automatic locking screw machine

The movement trajectory of the robotic arm is controlled by programming to realize the locking of screws at different positions.

It has the characteristics of high precision, high speed and high reliability, and is suitable for products with high requirements for lock accuracy, such as mobile phones, tablet computers, etc.

● Functions and features of automatic screw locking machine

Increase productivity

The automatic screw locking machine can quickly and accurately complete the screw locking operation, which greatly shortens the production cycle and improves the production efficiency.

Compared with the traditional manual screw locking method, the automatic screw locking machine can complete more locking tasks in the same time.

Ensure the quality of the lock

The automatic locking screw machine adopts a high-precision positioning system and locking tools, which can ensure that the locking depth and torque of the screws are consistent, so as to ensure the quality of the product.

It avoids the problems of leakage lock, tooth slippage, and insufficient torque that may occur when manually locking screws.

Reduce labor intensity

The automatic screw locking machine can replace manual work to complete repetitive and high-intensity screw locking work, which reduces the labor intensity of operators.

Fatigue and industrial accidents caused by long hours of operation are reduced.

Cost savings

Although the initial investment of the automatic screw locking machine is high, it can operate stably for a long time, reducing labor costs and rework costs caused by screw lock quality problems.

At the same time, the high efficiency of the automatic screw locking machine can also reduce the production cost of the enterprise and improve the competitiveness of the enterprise.

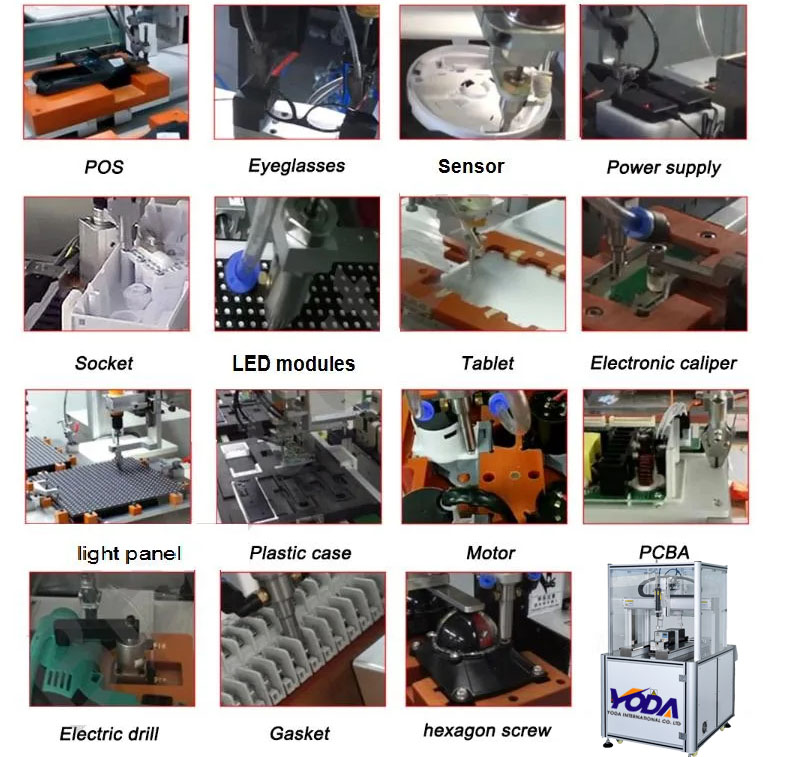

● The scope application of automatic screw feeder

Automatic screw locking machines are widely used in product assembly in electronics, electrical appliances, automobiles, machinery, furniture and other industries.

Assembly of electronic products such as mobile phones, tablets, laptops, etc.

Assembly of household appliances such as air conditioners, refrigerators, washing machines, etc.

Assembly of parts such as automobile engines, transmissions, and instrument panels.

Assembly of furniture, lamps, toys and other products.