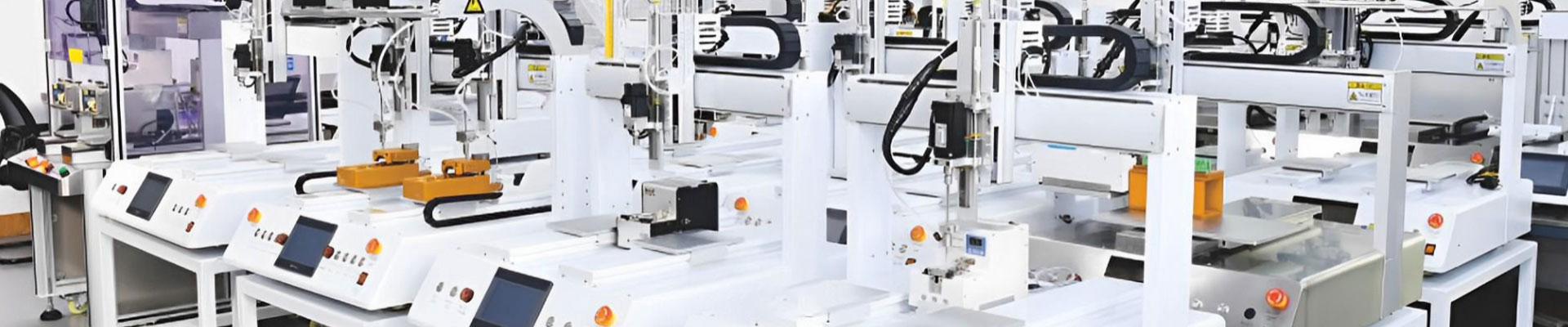

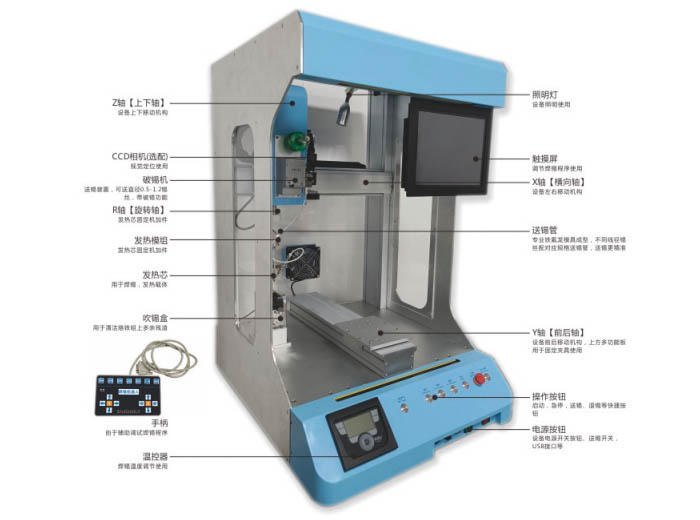

Product Description

Features of IoT Soldering Robot

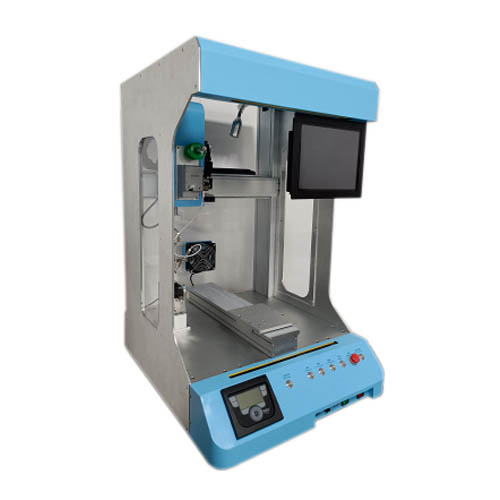

2. For Windows 7 system, there is no limit on the size of the soldering program. The machine is equipped with other functions to make it smoother and simpler: such as safety light curtains, optical components, infrared temperature measurement, preheating platform, MES system data interaction, etc., built-in dual temperature control real-time correction system and real-time curve monitoring of temperature control.

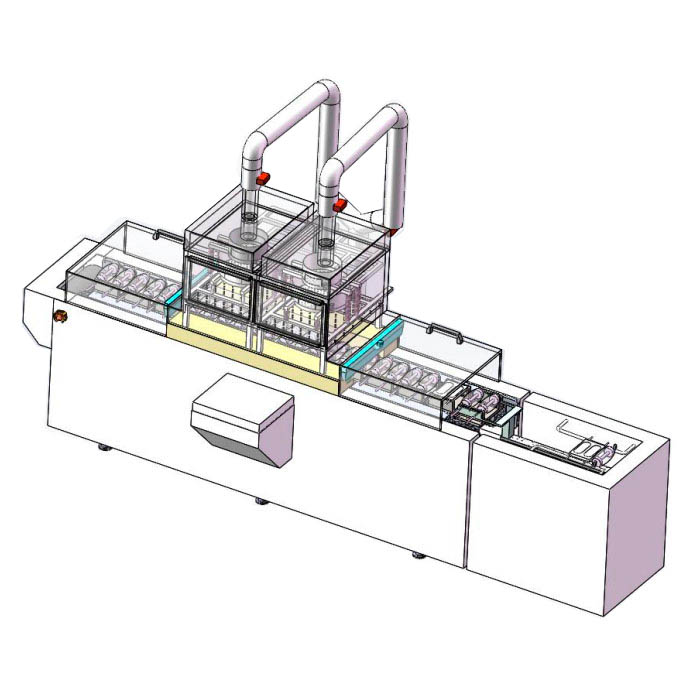

3. The follow-up smoking design can achieve smoke without blind spots and keep the air in the workshop clean.

4. The six-axis linkage manipulator is controlled by advanced PC algorithms, which effectively improves the accuracy of the machine.

5. Full touch operation and fool-like programming. During teaching, you can complete the setting of a solder joint with just a touch of your finger. There are no special skill requirements for the operator.

6. Flexible and diverse soldering methods, tin supply can be started at any time, effectively meeting various soldering process requirements and improving soldering efficiency.

7. Shake welding function: Turning on this function during welding can make welding faster, especially effective for welding large solder joints.

8. The unique concentric circle design of the heating module can realize circumferential welding of solder joints, which is especially effective for the welding of large disc solder joints and copper pillars.

9. All solder joint traces are clearly visible on the display screen, so the operator can better understand the welding status and program modification is more convenient.

10. After the program is set up, it can be optimized. When there are no obstacles between two adjacent welding items, after optimization, the machine will choose the shortest operating path to improve the machine's operating efficiency.

11. The soldering iron tip can be adjusted at any angle and direction. After setting, the machine can automatically calculate the running trajectory according to different directions and angles.

12. The machine automatically calculates the compensation point. You only need to specify the compensation distance between the plane and the space, and the machine can calculate the position of the compensation point. This function can effectively avoid fixing fixture errors and product errors, and is extremely effective for welding plug-ins.

13. The temperature control system adopts German Wilo heating core/high-power high-frequency heating core combined with an independent control system. It has a fast temperature return and a stable welding curve. It also has a frequency conversion function, which can achieve high and low temperature welding and low temperature alarm.

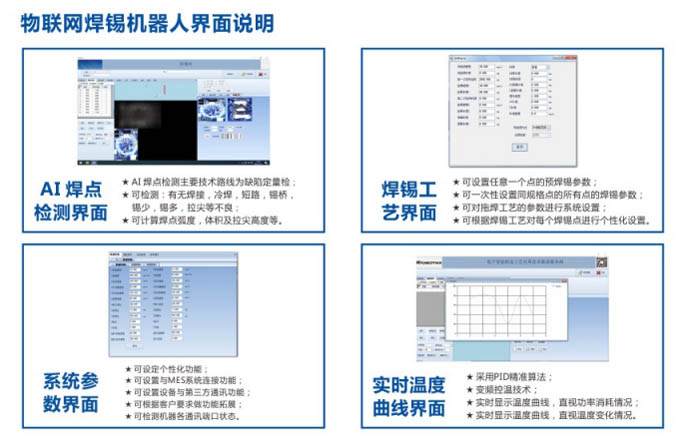

Interface Description