Product Description

The main technical route of solder joint inspection is quantitative defect inspection, which can detect whether there is welding, cold welding, short circuit, Solder bridge, solder insufficient, excessive solder,solder projections,etc.

It can calculate the arc, volume and tip height of solder joints.

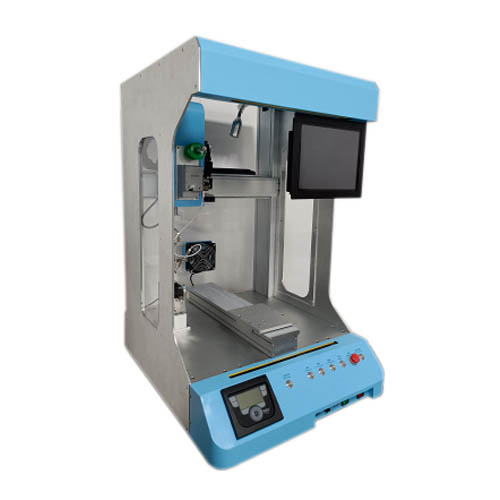

Technical parameter

| Model | 331RA | 441RA | |||

| Itinerary (other itineraries can be customized) |

X-axis | 300 | 400 | ||

| Y-axis | 300 | 400 | |||

| Z-axis | 100 | 100 | |||

| R-axis | 360° | ||||

| X-axis | 30° | ||||

| Repeat accuracy | X,Y,Z-axis | ±00.02mm | |||

| R,A-axis | ±0.02° | ||||

| Movement method | Five-axis visual positioning | ||||

| Feeding mode | Automatic loading and unloading | ||||

| Material feeding method | Double speed chain line | ||||

| Welding method | Spot welding, drag welding | ||||

| Heating module | WELLER 200W welding module【Optional WELLER 150/high power 400W/600W/800W】 | ||||

| XYZ module | Closed loop motor | ||||

| Workbench | 180° Flip horizontally 180° | ||||

| Speed | (XYZ)650mm/s R:180°/s | ||||

| Controller | PC regulation | ||||

| Program recording mode | The theoretical value is infinite | ||||

| Mode of motion | Five-axis rectangular coordinates | ||||

| Air pressure | 0.6~0.9Mpa | ||||

| Power supply | 100~240V | ||||

| Working temperature | 0~40°C | ||||

| Humidity | 20~90% | ||||

| Applicable tin wire diameter | 0.4~1.2mm | ||||

Technical Features

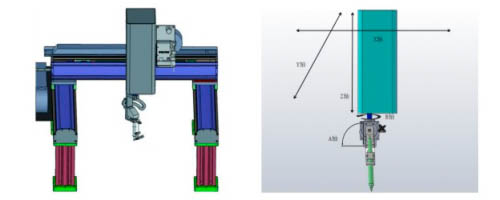

Five-axis visual positioning

MARK point visual positioning is used to support XYZRA five-axis position offset calibration, greatly improving the versatility of the equipment.

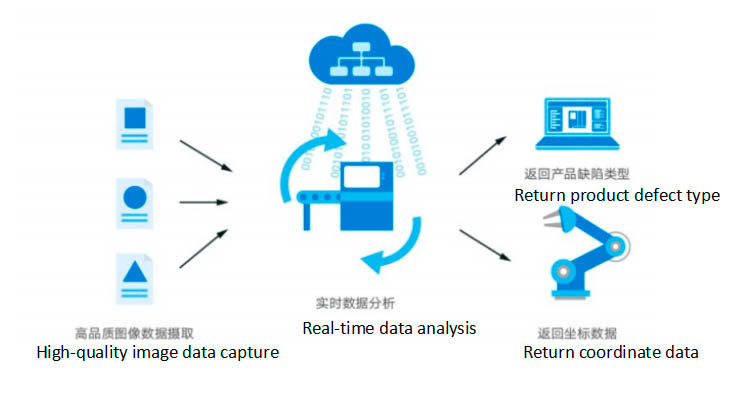

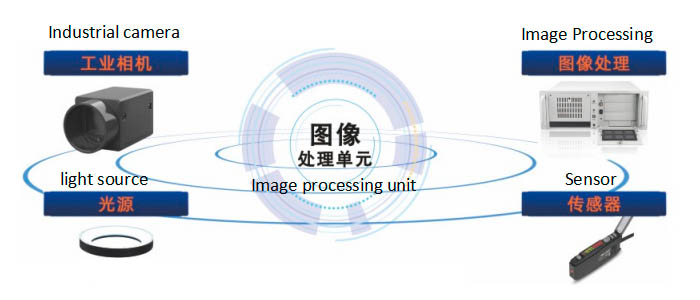

The cognitive visual inspection technology used in the inspection system integrates industrial robot control technology, high-speed industrial photography technology, computer vision technology, AI algorithms based on deep neural networks, and machine learning technology.Through standardization, automation, and intelligence, it provides end-to-end It realizes all-round appearance quality inspection on the end, and is used in solder joint visual inspection, coating visual inspection, dispensing visual inspection and PCB finished product inspection, etc.

Solution

2. AI intelligent detection engine for detection: Submit the collected photos to the AI intelligent detection engine for detection. The efficient algorithm supports detection within 1 second.

3. Detection of unqualified solder joints - Based on statistical analysis of data, the solder joints detected using AI intelligence are verified and compared the unqualified solder joints detected by traditional human eyes.

Test icon

AI industrial inspection VS traditional AOI(Check statistics with AVI appearance)

| Number | Comparison item | AI method | Traditional AOI method | ||||

| 1 | Missed detection rate | Within 0.2%, no obvious defects are missed. | More than 10% | ||||

| 2 | Pass inspection rate | Within 5% | More than 20% | ||||

| 3 | Save manpower | One device replaces 16 people | |||||

| 4 | Hardware | Only simple visual equipment is needed | Extremely demanding requirements on optical systems | ||||

| 5 | Operator quality | Simple operation, low requirements for personnel cultural level |

The operation is complex and requires a high level of education |

||||

AI Detector Detection Basic Process