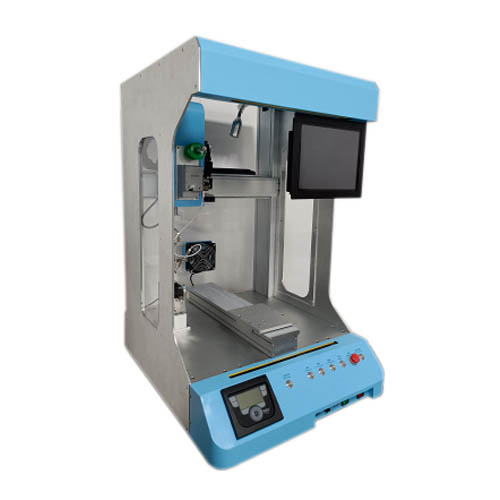

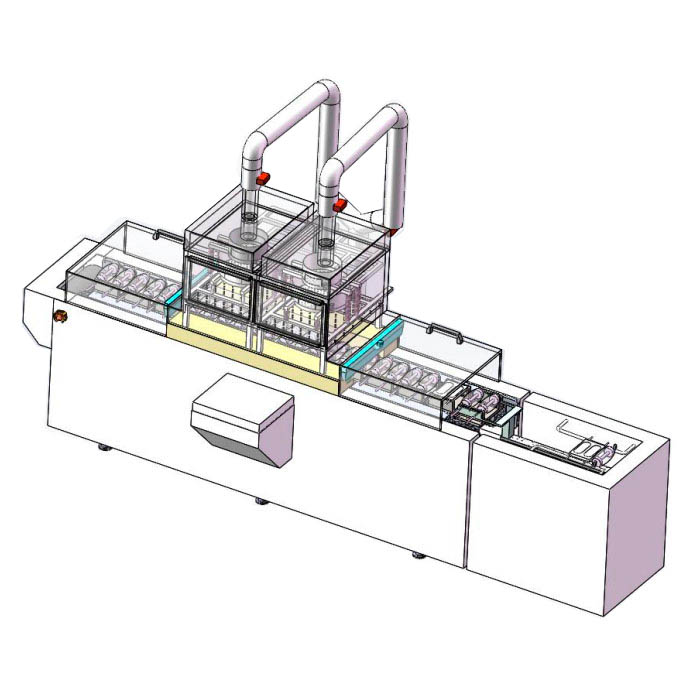

Product Description

The high-performance laser soldering system is a soldering equipment specially provided for parts with small size or narrow joints.

The non-contact method not only requires less consumables and low operating costs, but also makes daily maintenance relatively simple.

Technical Parameter

| Model | HX-J331R | HX-J441R | ||

| Itinerary (other itineraries can be customized) |

X-axis | 300 | 400 | |

| Y-axis | 300 | 400 | ||

| Z-axis | 100 | 100 | ||

| R-axis(bottom) | 360° | |||

| Repeat accuracy | X,Y,Z-axis | ±0.02mm | ||

| R-axis | ±0.02° | |||

| Power supply | 220V 50Hz | |||

| Total power | 600W-1.5KW Optional according to configuration | |||

| Laser parameters | 10W-150W optional | |||

| Laser wavelength | 808nm/980nm/1064nm/1070nm(optional) | |||

| Control method | Microcomputer + PC image processing | |||

| Visual positioning system | ±0.03mm | |||

| Processing range | 300*300mm can be processed≤ 0.15pitch | |||

| Tin method | Premade tin/dot solder paste optional | |||

| Machine dimension(L*W*H) | 110×1100×1700mm | 120×1200×1700mm | ||

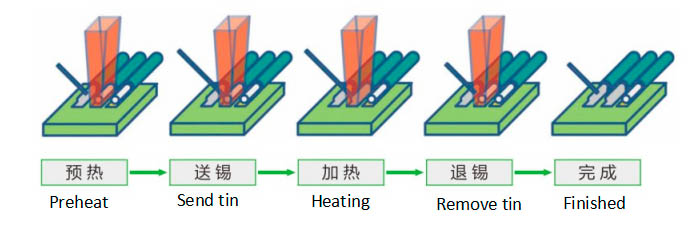

Laser Soldering Process

In the case of tin supply, it is important to irradiate the soldering point (preheating) to the component to be soldered (mainly the electrode component) in advance and to spread the soldering wire without resistance when it comes into contact with the soldered component.

In the case of solder paste, the solder paste is pre-applied where solder is required, so the preheat is directed to the solder paste.A heating process using gradually increasing laser power is used. This gradual heating process effectively prevents solder paste from flying away.