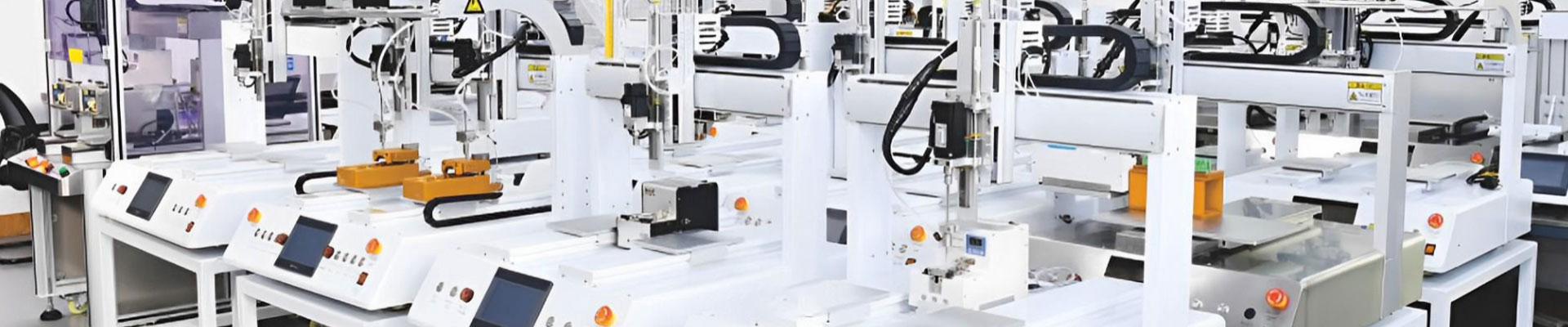

Product Description

● The drop-type screw structure can realize the lock function of the standard surface structure of the product lock screw position.

● Double-mode left and right alternately locks two different screws (or operate separately) to replace the product to achieve high efficiency working mode

● Supports missing locking/ tooth sliding/tooth floating alarm function

● Supports the adjustment function of front-loading and rear-taking or front-loading and front-taking

● Supports auto-sensing startup function

● Supports servo electric batch speed and torque self-adjusting function

● Supports hand drag adjustment to lock screw point adjustment function

Product Parameters

| Screw locking range (X*Y1*Z*X*Y2*Z) | 230×5000×135×230×500×135mm |

| Screw locking time | 0.8~1.2s/pcs |

| Repetitive accuracy | ±0.03mm |

| Program recording mode | 15 groups,99 points per group |

| Electric batch mode | Precision servo motor (Mitsubishi/Delta) |

| Feeding mode | Direct screw feeding(self-owned brand) |

| Control system | MCU + touch screen control system |

| Motor system | Precision stepping(closed loop) motor(domestic brand) |

| Driving mode | Synchronous belt/precision linear guide(Taiwan HIWIN) |

| Input power supply | 220V/50HZ |

| Working air current | 0.4~0.6MPA |

| Edit mode | Hand drag & teaching |

| Working environment temperature | 5~40° |

| Humidity of working environment | 20-90% |

| Applicable screw specifications | PB/KB head type screws (including stainless steel screws) except meson type |

| Suitable for locking screw size | M1.5~M4 (the screw length does not exceed 16mm),customized if it exceeds the range,screw length ratio must comply with 1:1.5 |

| Machine size(L*M*H) | 950x720x900mm |

| Machine weight | 100KG |

Product Application

Manufacture Ability

Yoda Machinery Equipment is a professional equipment company specializing in the research and development, production and sales of automatic locking screw machines and non-standard automation, and enjoys a high reputation in the industry.